Isihlungi Se-Melt Polymer Strainer Pleated Amafutha

Isingeniso

Izihlungi eziboshiwe zakhiwe ngamashidi emidiya anemihlobiso, okuwenza asebenze kangcono kunezinye izihlungi mayelana nokuthwebula i-particle nokuthuthukisa ikhwalithi yomoya noma yoketshezi.Asetshenziswa ezinhlelweni ezahlukahlukene, njengezinhlelo ze-HVAC, izindawo zamanzi zasemanzini, nezinhlelo zamanzi, ezizuza endaweni engaphezulu ekhulayo namandla okuhlunga anamandla ezihlungi ezinamaqabunga.Izihlungi eziboshiwe zingahle futhi zakhelwe ngosayizi othize wezinhlayiyana futhi zize ngezinhlobonhlobo zomumo nosayizi, okuzivumela ukuthi zisetshenziswe ngempumelelo nangempumelelo ezilungiselelweni ezihlukahlukene.

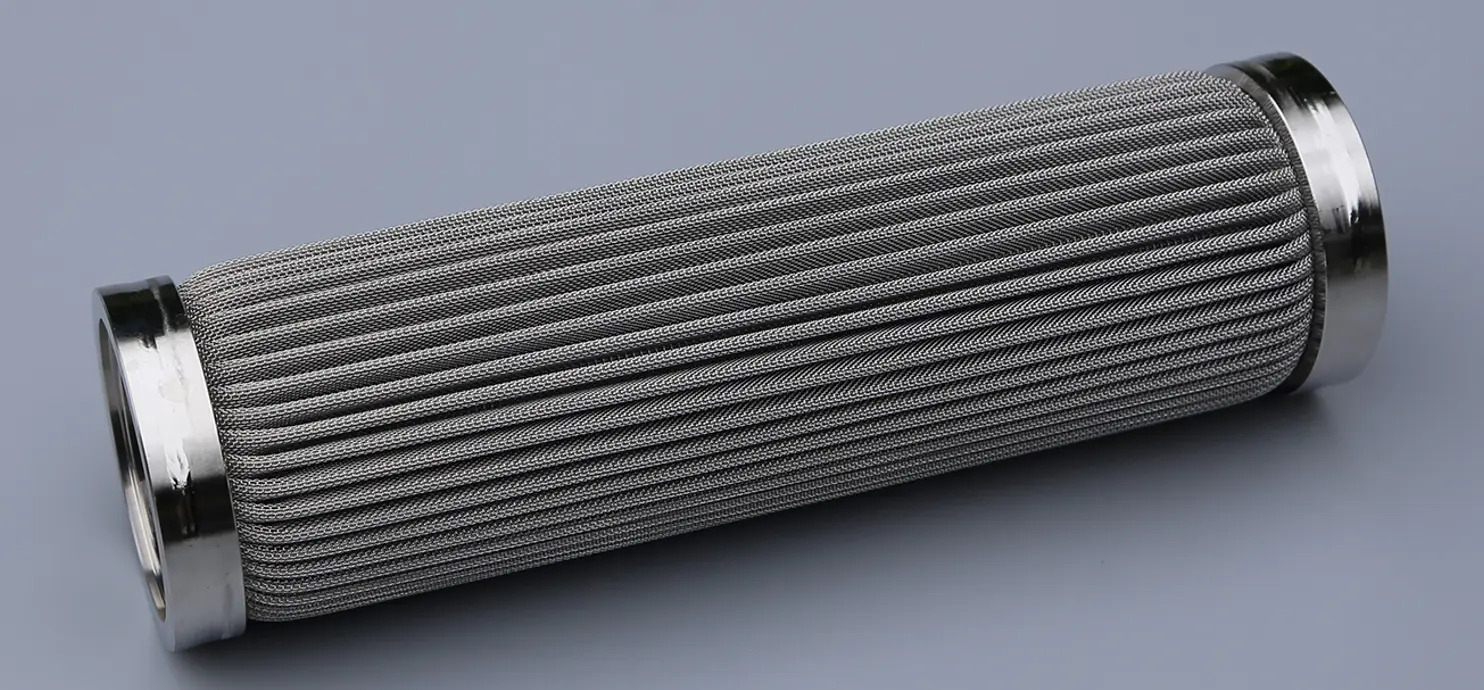

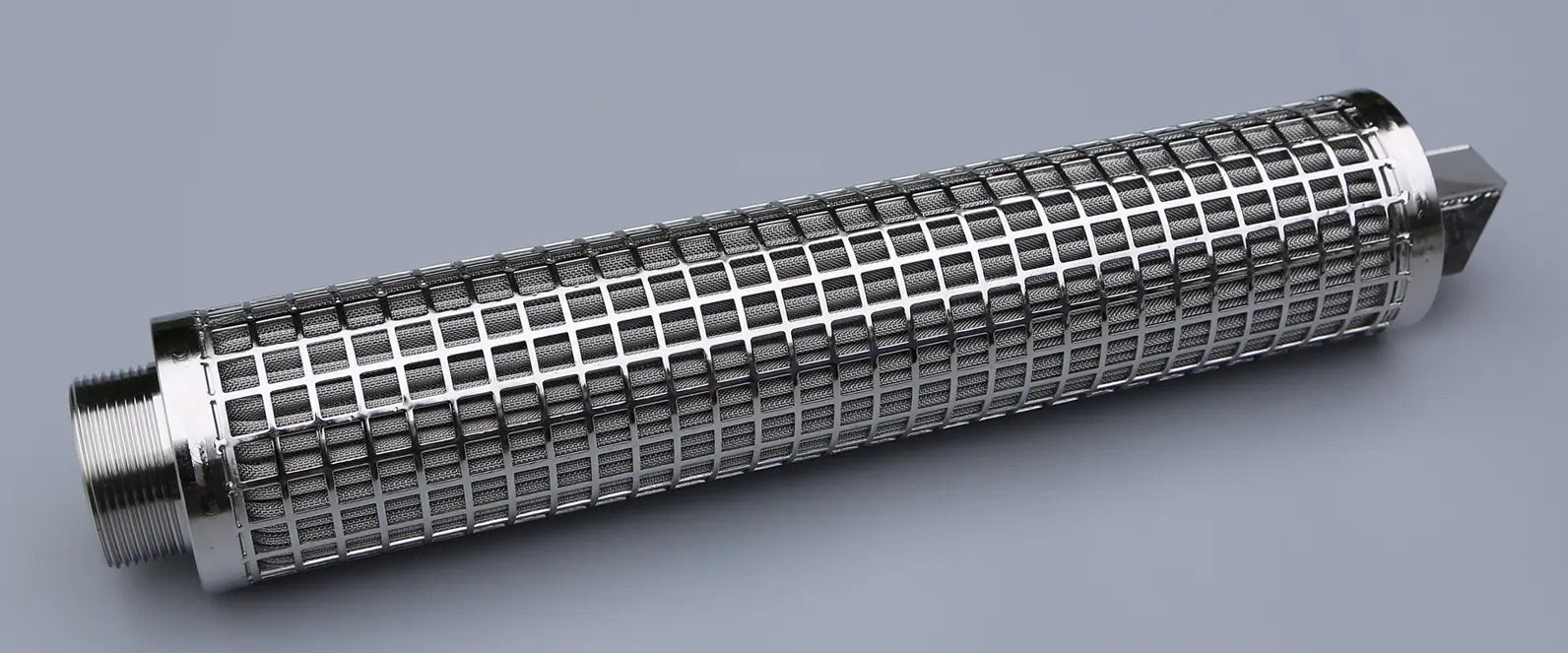

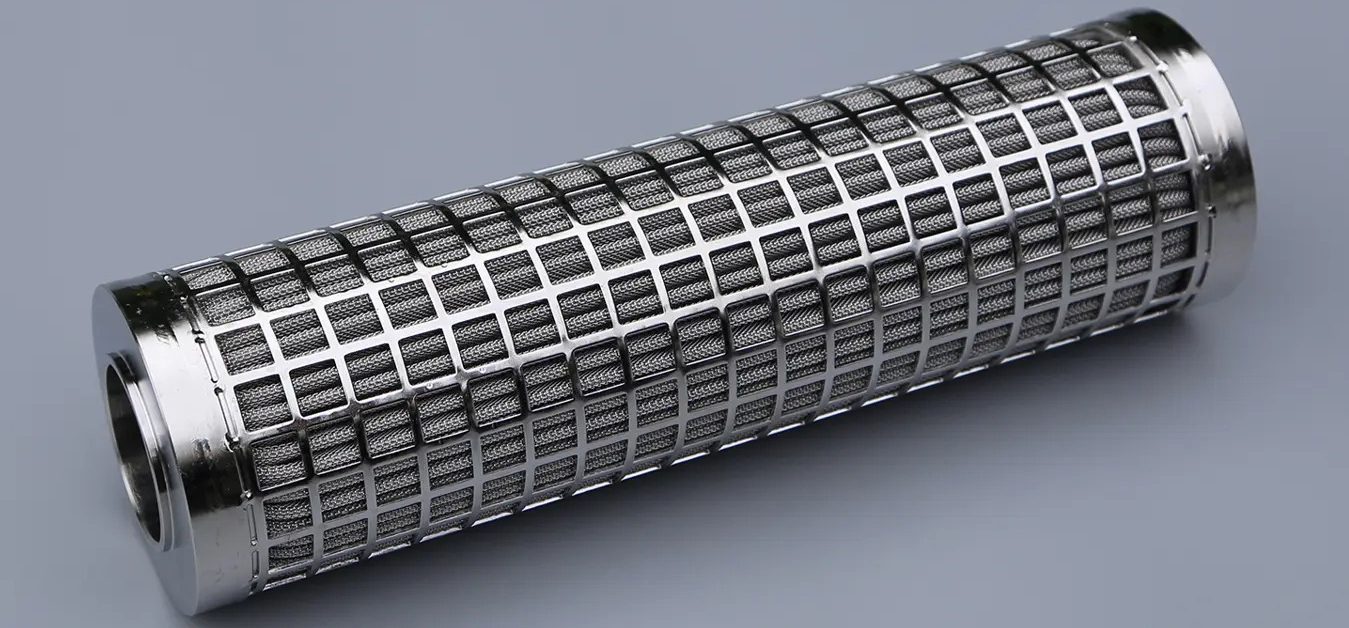

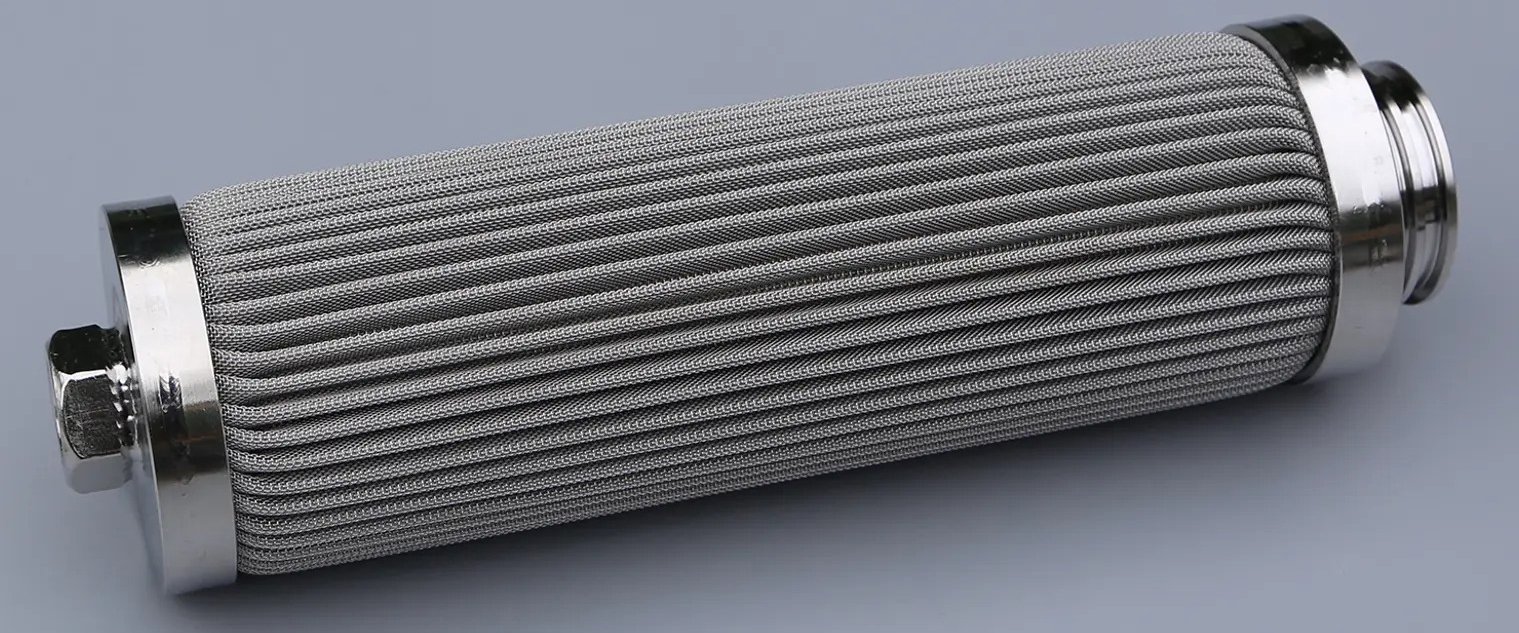

Ukucaciswa

Isihlungi semidiya eyinhloko Yesihlungi Se-Pleated senziwa ngensimbi engagqwali yocingo olulukiwe lwemeshi kanye nensimbi engagqwali i-fiber sintered feeling.

Izinto zokuhlunga eziyinhloko zifaka i-304, 304L, 316, 316L, 904L, Monel, Hastelloy njll.

● Izinga lokuhlunga: 3-200μm

● Izinga lokushisa: -50℃-800℃

● Ububanzi: 14-180mm, Ubude: 35-1500mm

● Okwenziwe ngokwezifiso nakho kuyatholakala.

| Isilinganiso Sesihlungi Esiphelele (μ) | I-Bubble Pion Pressure (Pa) | I-Average Air Permeability (l/dm2/min) | Ubugqinsi (mm) | Isisindo (g/m2) | I-Porosity (%) | Ukungcola Ukubamba Umthamo (mg/cm2) |

| 3 | 12300 | 9 | 0.35 | 975 | 65 | 6.40 |

| 5 | 7600 | 34 | 0.34 | 600 | 78 | 5.47 |

| 7 | 5045 | 57 | 0.27 | 600 | 72 | 6.47 |

| 10 | 3700 | 100 | 0.32 | 600 | 77 | 7.56 |

| 15 | 2470 | 175 | 0.37 | 600 | 80 | 7.92 |

| 20 | 1850 | 255 | 0.49 | 750 | 81 | 12.44 |

| 25 | 1480 | 320 | 0.61 | 1050 | 79 | 19.38 |

| 30 | 1235 | 455 | 0.63 | 1050 | 79 | 23.07 |

| 40 | 925 | 580 | 0.66 | 1200 | 77 | 25.96 |

| 60 | 630 | 1000 | 0.70 | 750 | 87 | 33.97 |

Isicelo

1. Indawo enkulu yokuhlunga, Uhlu olubanzi lokunemba kokuhlunga

2. Izinga eliphezulu le-porosity, Ukungena komoya okuhle kakhulu kanye nekhono lokuhlunga.

3. Umthamo omuhle wokubamba ukungcola, Umnotho.

4. Ukumelana nokushisa okuphezulu, ukumelana nokugqwala njll.

5. Ukuhlanza okulula, Okugaywa kabusha.

Isici

1) Imboni ye-polymer ephezulu

2) Imboni ye-Petrochemical

3) Imboni yokuhluza imithi nokudla

4) Ukwelashwa kwamanzi

5) Izimboni zemishini nezikebhe

6) Ukuhlanzwa komoya

I-7) Abanye: Ukushisa okuphezulu, i-viscosity ephezulu, ukucindezela okukhulu.

Bonisa